Anti-static film is very important for the protection of electronic products. Our company specializes in producing special anti-static film for electronic products, which can effectively prevent electrostatic damage to the circuit.

Production process: Anti-static film is produced by adding imported anti-static agent into PE raw material to make its surface resistance reach 10~10Omega. Friction itself does not produce static electricity, after high temperature setting, wear-resistant, thus playing a good anti-static effect. Avoid static electricity damage to human body, products and work site. Surface resistance:10~10Ω Characteristic: High temperature and durable wear resistance. |  |

|

It is used for the outer packing of electronic products. It has the functions of |

In addition to the above illustrated products, we also provide BOPP, PET and other antistatic films with surface resistance less than 109Ω。 | |

● Excellent antistatic ability, can be extended according to the appearance of the product attachment, so that the shape and appearance of the product is clear, beautiful and neat, increase customers'desire to buy. ● Good protection: laminated circuit board or multiple components can be fixed after packaging, each piece is close to each other, won't damage the product during transportation, good fixity, will never produce scratches caused by mutual friction; ● Moisture-proof: Vacuum packaging film and articles are fully consistent, space is minimal, with excellent moisture-proof, no need for moisture-proof agents, cost savings; ● Anti-oxidation, anti-penetration and anti-rust. |  |

|

|

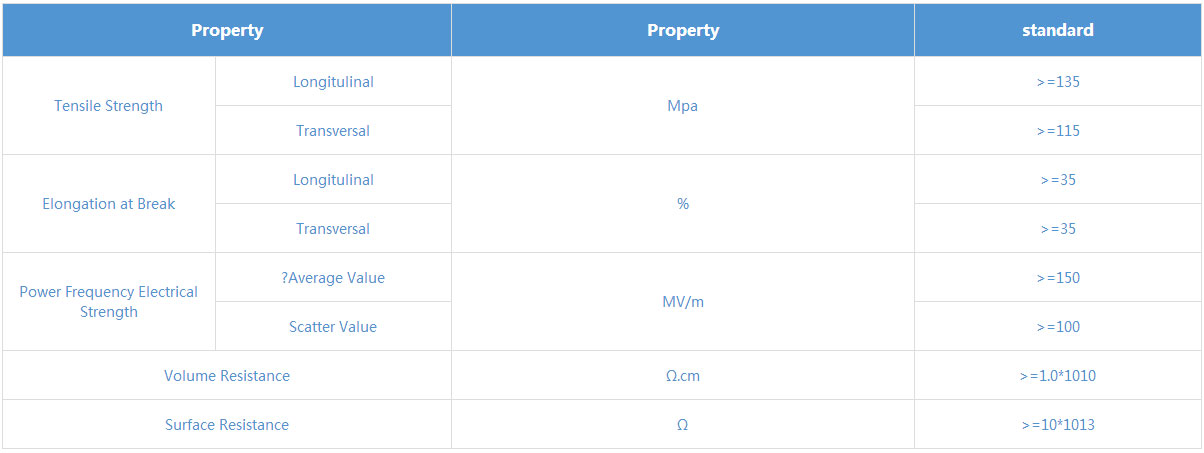

Product characteristics 1. Temperature range from -452℉(-269℃) to + 436℉(+260℃) 2. High and low temperature resistance. 3. Good stiffness. 4. Better insulation performance. 5. Radiation resistance. 6. Perfect durability and reliability. |  |